-

Bevel Gear Reducer

-

Helical Gear Reducer

-

Cycloidal Gear Reducer

-

Planetary Gear Reducer

-

Worm Gear Reducer

-

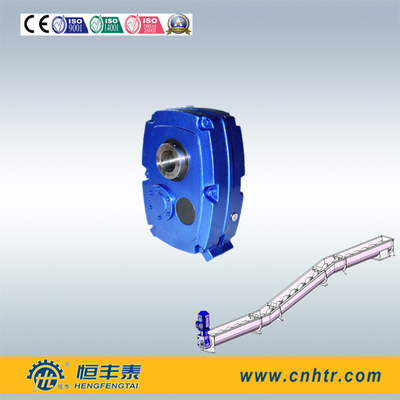

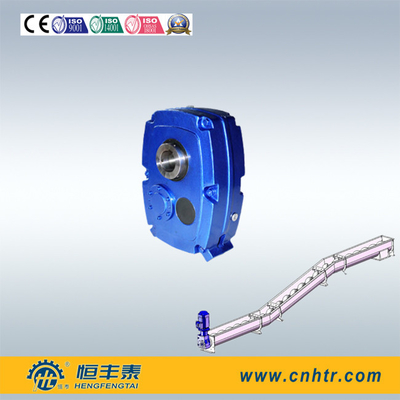

Shaft Mounted Speed Reducer

-

Planetary Speed Reducer

-

Cycloidal Speed Reducer

-

Electric Motor Gearbox

-

Liquid Mixer Agitator

-

Industrial Planetary Gearbox

-

Magnetic Lifting Equipment

-

Solid Liquid Separation

-

Industrial Mixer Blades

-

Michale-USAHENGTAI has performed all the responsibilities. Its gearbox operates safely and steadily with lower noisy and good quality.

Michale-USAHENGTAI has performed all the responsibilities. Its gearbox operates safely and steadily with lower noisy and good quality. -

Matías Salvati-ArgentinaThe HXG shaft mounted gearbox bought in 2015, it operates steadily, continuous working without faults, has perfect after-sale service.

Matías Salvati-ArgentinaThe HXG shaft mounted gearbox bought in 2015, it operates steadily, continuous working without faults, has perfect after-sale service. -

Haleem-UAEVery nice products I always buy from HFT, with a very good quality and competitive price, also the salesman in HFT is very nice too.

Haleem-UAEVery nice products I always buy from HFT, with a very good quality and competitive price, also the salesman in HFT is very nice too.

High Torque Helical Gear Reducer Horizontal Shaft Mounted Speed Reducer

| Highlight | inline helical gearbox,helical bevel gearbox |

||

|---|---|---|---|

High Torque Helical Gear Reducer Horizontal Shaft Mounted Speed Reducer

Quick Details:

|

Torque: |

256 to 44.000 Nm |

|

Ratios: |

5:1, 13:1, 20:1, 25:1 |

|

Power: |

0.18 kW to 280 kW |

|

Sizes: |

103 to 608 |

|

Bore sizes: |

30 to 190 mm, optionally in inches |

|

Mounting: |

Vertical, Horizontal, and Direct drive mounting configurations |

|

Lubrication: |

Oil lubrication, synthetic lubricant optional |

|

Housing: |

Grey cast iron |

Description:

· CASE MATERIALS ARE GG 25 FOR FROM P1 TO P4 AND GGG40 FROM P5 TO P10

· CASE HAVE MORE STRENGTH AND ESTHETIC VIEW

· PLACE FOR BEARINGS ARE MACHINED ACCORDING TO STANDARDS

· LONG LIFE CYCLE IS CONSIDERED FOR SELECTING BEARINGS

· GEARS MATERIAL IS SAE 8620 FORGING MATERIALS AND ISOTHERMIC TEMPERING IS APPLIED

· CARBURIZING IS APPLIED ACCORDING TO MODULE OF GEARS AND ADJUSTING HARDNESS DEPTH

· GRINDING AND SCRAPING ARE APPLIED TO GEARS

· SHAFT MATERIAL IS SAE 1050 STEEL AND TOLERANCES ARE ADJUSTED ACCORDING TO STANDARD NORMS

|

SIZES |

A |

B |

C |

D |

E |

F |

Input Shaft Keyway |

H |

J |

K |

P |

T |

U |

V |

W |

X |

Y |

|

|

Hub Dia |

||||||||||||||||||

|

STD |

ALT |

|||||||||||||||||

|

B |

134 |

30 |

40 |

63 |

59 |

80 |

19j6 |

6x3.5x50 |

104 |

131 |

55 |

10 |

186 |

226 |

81 |

75 |

25 |

79 |

|

C |

142 |

40 |

50 |

72 |

65 |

90 |

22j6 |

6x3.5x5.6 |

108 |

156 |

59 |

10 |

218 |

270 |

96 |

90 |

31 |

95 |

|

D |

152 |

50 |

55 |

77 |

68 |

100 |

25j6 |

8x4x63 |

118 |

188 |

76 |

12 |

258 |

328 |

117 |

110 |

37 |

116 |

|

E |

170 |

55 |

65 |

85 |

76 |

115 |

28j6 |

8x4x70 |

130 |

222 |

90 |

12 |

278 |

377 |

129 |

125 |

43 |

133 |

|

F |

189 |

65 |

75 |

90 |

87 |

130 |

32k6 |

10x5x70 |

149 |

242 |

98 |

16 |

317 |

414 |

143 |

141 |

50 |

150 |

|

G |

212 |

75 |

85 |

105 |

110 |

145 |

42k6 |

12x5x90 |

172 |

277 |

110 |

16 |

365 |

468 |

162 |

156 |

56 |

166 |

|

H |

242 |

85 |

100 |

116 |

115 |

170 |

48K6 |

14x5.5x100 |

190 |

330 |

88 |

16 |

434 |

550 |

195 |

189 |

62 |

200 |

Your benefits:

The range of the metric based Shaft Mounted Speed Reducers (SMSRs) stands tall amongst the crowd.

Packed full of attention to detail, the SMSRs deliver performance in the harshest of applications.

Shaft mounted drives remove the need for couplings, mounting plinths and have infinitely variable ratios due to the belt drive.

They are also incredibly simple to fit and can be mounted in any position as no motor base is required.

Applications:

- Road Construction Machinery

- Mining & Minerals Industry

- Cement Industry

- Chemical Industry

- Coal Industry

- Salt Industry

- Ceramic Industry

- Sugar Industry

- Paper And Pulp Industry

- Iron And Steel Industry

- Pharmaceuticals Industry

- Textile Industry

- Leather And Plastic Industry

- Food Processing Industry